Stop coordinating between design firms, usability consultants, and manufacturers. Get expert design services, human factors analysis, research, guidance, and flexible manufacturing in one place.

No minimum orders.

No untested large production runs.

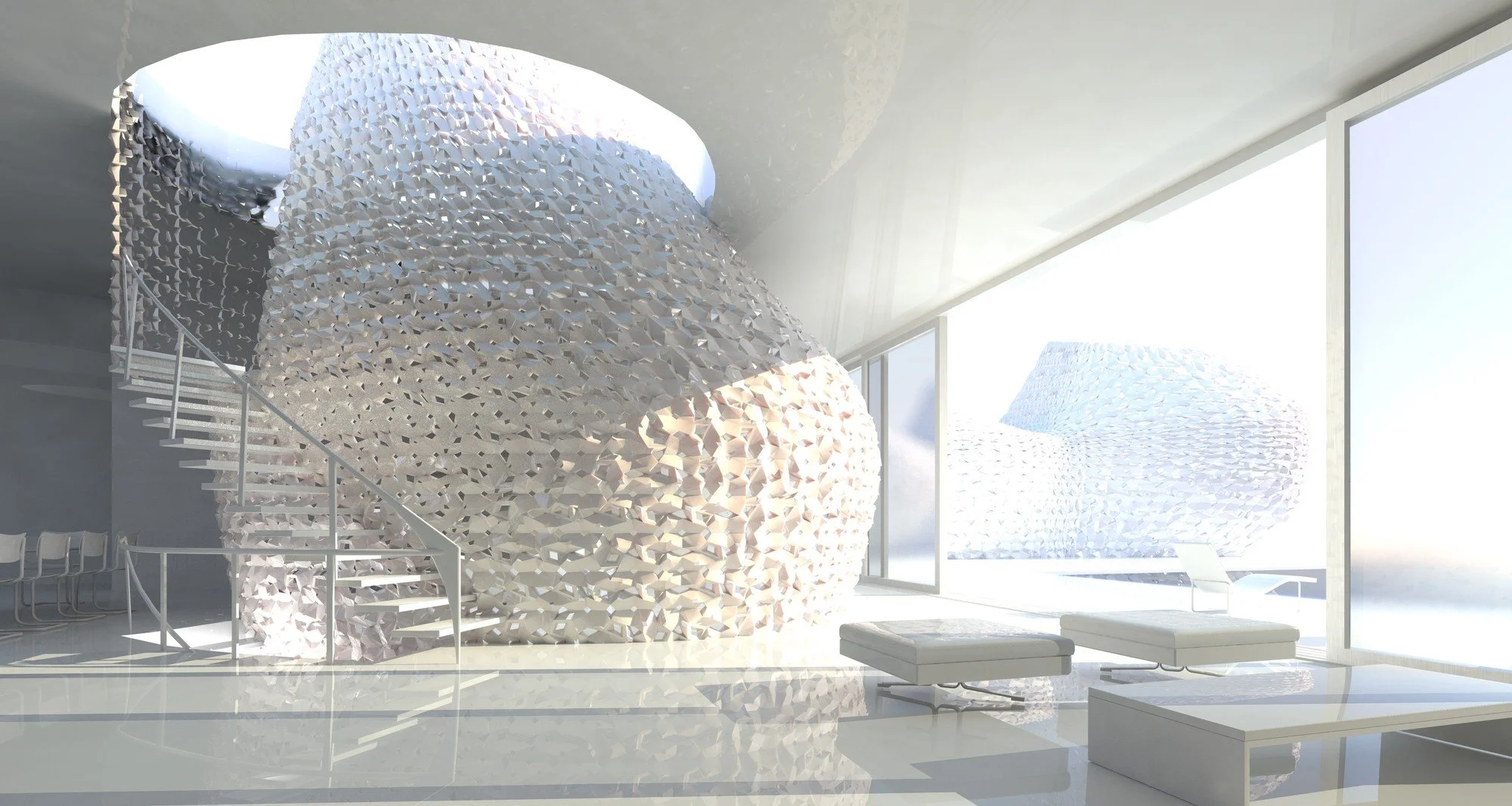

Welcome to Wexley House

Wexley House eliminates these risks by combining:

Industrial design expertise

Human factors analysis

Flexible small-batch production on one integrated platform.

Traditional Manufacturing Wasn't Built for Innovation

Hardware development requires multiple specialists: industrial designers for aesthetics, usability consultants for ergonomics, R&D teams for technical feasibility, and manufacturers for production. Coordinating these vendors creates delays, increases costs, and fragments your vision.

Worse, traditional manufacturers demand 5,000+ unit minimums before you've validated market demand. This forces untested production commitments that lead to the 70% failure rate among hardware startups.

Integrated Services. Small Batches. Physical Validation.

Services

-

Utilizing our 3D printing studio we work with Industrial product designers, from things as simple as enclosure development, material selection, and aesthetic refinement. To things higher in difficulty. We optimize form factor and specify finishes that align with your technical requirements and user needs.

-

User interaction analysis, ergonomic evaluation, interface design, and accessibility considerations. We ensure your product works for real users, not just in theory.

-

Technical feasibility assessment, engineering problem-solving, material guidance, and design for manufacturability. We help you navigate technical challenges while maintaining design integrity.

-

Test quantity production with no minimum orders. Our parametric manufacturing tools connect design specifications directly to fabrication equipment, enabling rapid iteration and physical validation.

Contact Us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!